This could be interesting

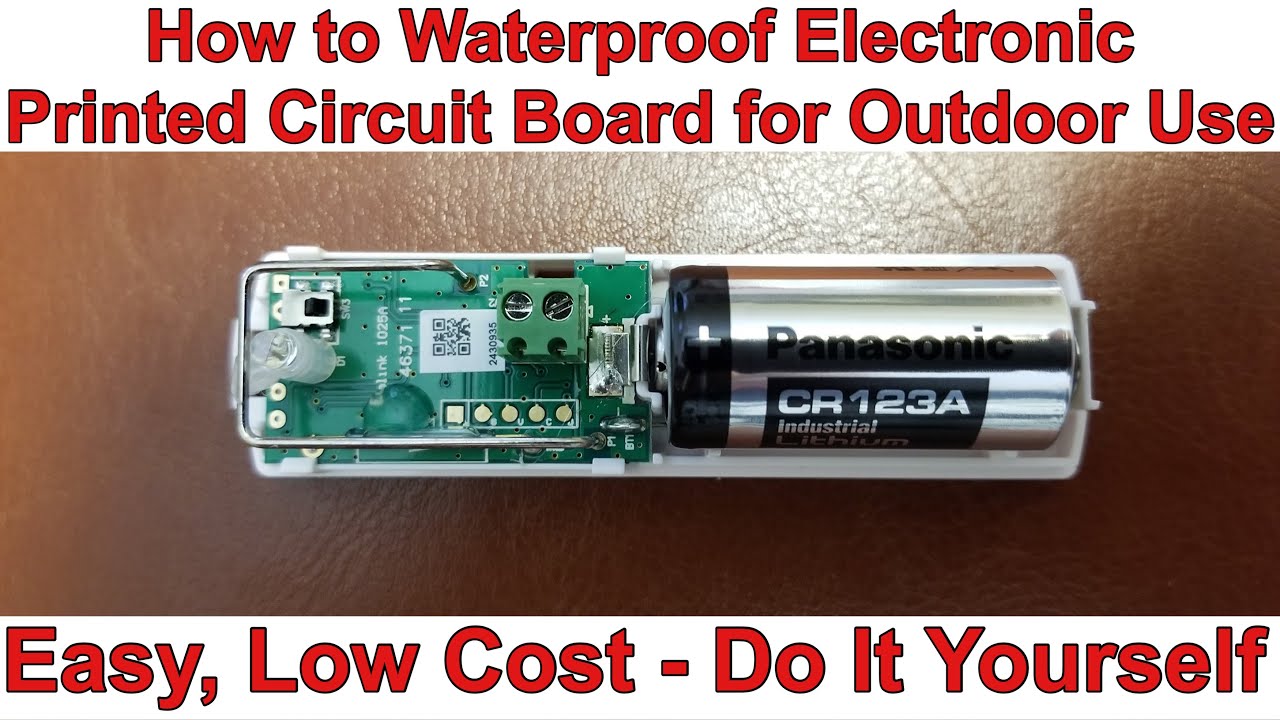

I use the spray version and it works great. The coating stops the board from collecting dirt and corroding. One still needs to keep direct rain off the battery and contacts.

Interesting…

Funy story - I have that exact sensor outside on a fence door, it is not waterproofed. It stopped working one day and I figured the elements must have gotten to it, only to find that something had hit it and the board and battery were in a puddle of water (probably been there for a couple of days…). I let it dry and decided to see if it still worked. It did! It’s been close to 6 months now and it is still working without issues.

So… I wonder if it might have already been waterproofed at the factory…?

Regardless, thanks for sharing! Just ordered a bottle!

Wish I had remembered about this stuff before placing a sensor that similarly ended up falling into a puddle. Sure enough it worked after a good cleaning with alcohol but....I swear the thing is going through batteries a tad faster.

Sprays might be the thinner acrylic coatings like:

Doubtful. Electronic boards are washed in water (special clean water) in normal PCB assembly process. One of our TV remote controls went through the laundry and survived, just needed to be dried out thoroughly.

Acrylic coating is great for electronic boards. We used a product called Humiseal Acrylic coating which met all our environmental requirements. Personally I prefer Silicone based conformal coating for my personal use. It goes on thicker and is mechanically resilient.

Either will be far better than having uncoated boards.

I have an indoor Aqara (Zigbee) door sensor attached to my main exterior gate. I sprayed it on the outside with conformal coating, and then sprayed it to match my gate’s color, and it is sitting under direct sun (a lot) and rain (not so much here).

It has been running as a champ for more than a year now. I’m really surprised.

Zooz has this.

I've got Iris V1 contact sensors on my two gates that have been outside for almost 6 years without any waterproofing.

I have Iris Motions in similar duty without waterproofing (just positional protection) but this thread reminds me about a few things....

-

When you find a sensor and form factor that works really well in a location & application (i.e. problem solved) you tend to want to replace it with the same if you EVER have to.

-

Sometimes electronics don't get better with evolution, sometimes they get "cheaper in quality" ...so finding another one as good as the version that worked isn't always a given

-

Sometimes whole lines cease to exist, as in the case of Iris

-

A little waterproofing to prolong the life of anything outside is a good practice

I appreciate this reminder that the OP provoked.

Thinking about this waterproofing stuff further....

I wonder if there is a cautionary addendum we should be adding here, as in what individual components this would be a bad thing to coat "willy nilly".

I don't know if there is anything on these boards that would fail faster by having any heat retention due to air exchange around them being less efficient.

I'd think coating temperature reading components would just insulate them and just make their temp responsiveness/changes a little slower at worst.

But as for humidity... I actually have never looked at the component(s) that are involved on these small environmental sensors but I'm thinking it would be a bad idea to get this conformal coating anywhere near where they are meant to sample air.

Any adds?

Has anyone waterproofed a motion sensor? I have several that are outside (fairly protected) but I think that they may be vulnerable during hurricane season or some of our stronger summer storms.

Chemically no, physically yes....or at least attempted.

As long as the wind direction is not smack dab in the direction of this pipe I'm good. Snow has accumulated at the pipe end but water has rolled out. Hurricane, been there...done that...all bets are off. You might not even find it afterwards ![]()