@Velvetfoot , the 0-10 V thing is a big one I think as there were precisely zero solutions for zWave or Zigbee control aside from the Leviton product which (up to now anyway) was never documented

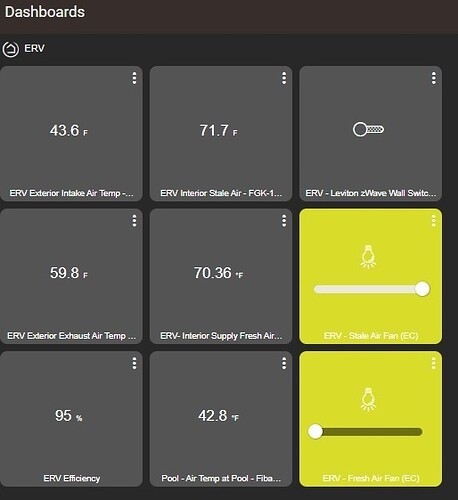

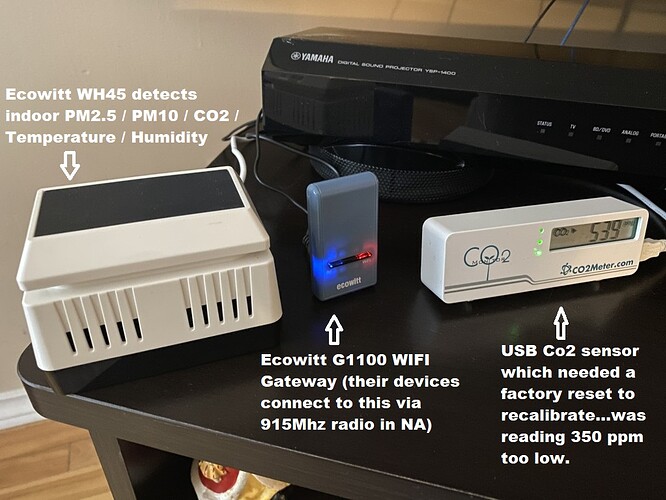

I do have DS18B20 sensors in each of the four air streams as you can see below:

I have a virtual Temp sensor which calculates live ERV efficiency values based on those temps, bottom left in the pic. There are also a few more sensors (like the Pool - Air temp) which are used in summer to control my pool solar heating system. That one gives me outside ambient temps, which correspond pretty closely with the "ERV Exterior Intake Air Temp".

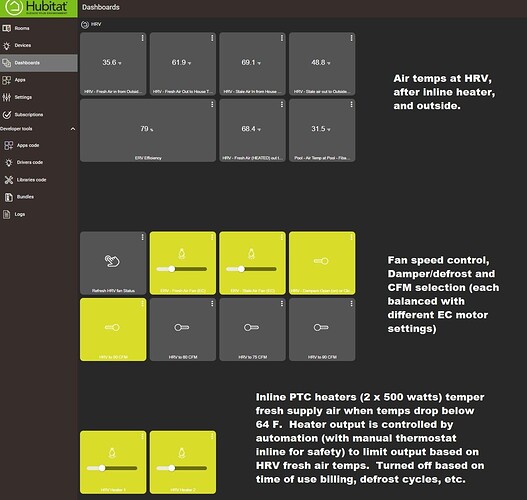

If the device has 0-10v control, you can likely use the Levition 0-10V dimmer to control it. Radon is a not a big issue for most here, but regardless, you don't want a house under negative pressure (pulling air in) particularly in very cold temps. Controlling your HRV this way (with two ECM motors) allows you to "add" some air into the house when for example the kitchen exhaust fan is fired up.

You're not off base at all..you get it  To me, having an option for 0-10V control that can integrate with Hubitat or Smarthings has a lot of possible uses here in NA for smarter homes. That's why I was pretty stoked to get this working.

To me, having an option for 0-10V control that can integrate with Hubitat or Smarthings has a lot of possible uses here in NA for smarter homes. That's why I was pretty stoked to get this working.

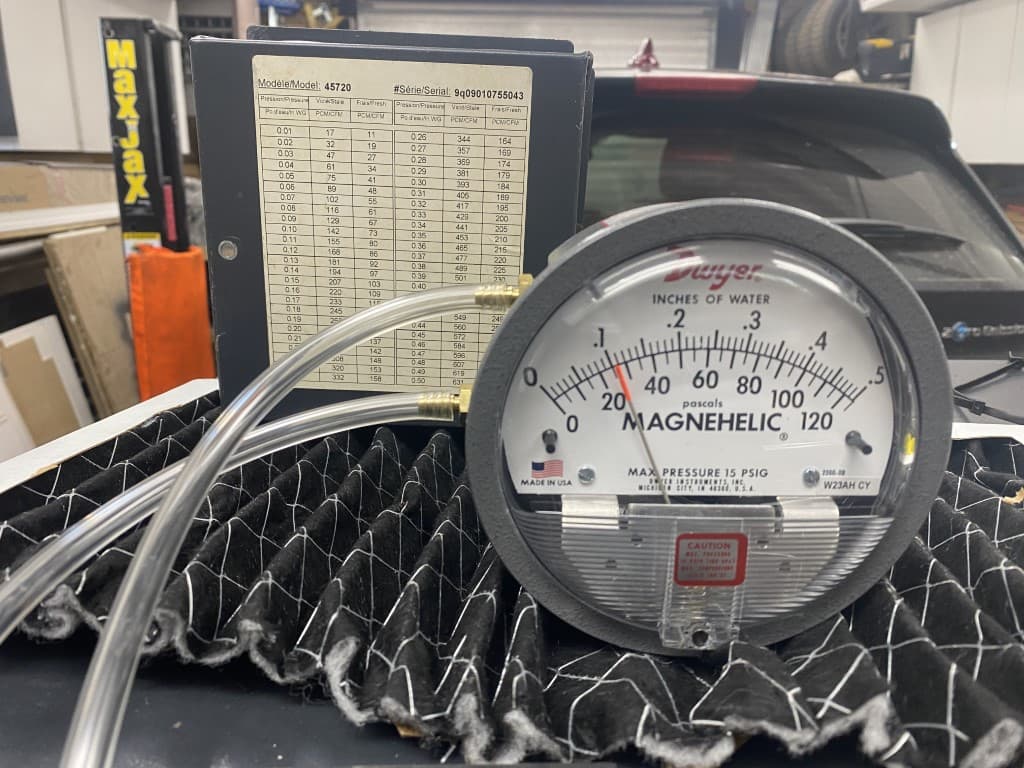

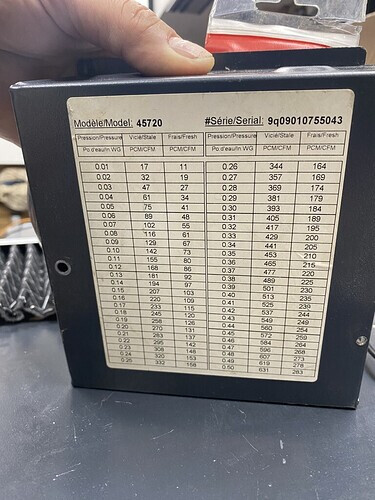

In general, you want air coming inside the house via an HRV/ERV to match air leaving. The magnehelic differential gauge lets you measure that using the HRV door ports. You use the balancing chart that is posted on your HRV/ERV to convert the magnehelic readings to CFM. I just tweak the motor speeds (via Hubitat) until the magnehelic (inches of water) reading matches the chart for my target CFM readings. Hope that makes sense.

I'm no expert...just learning as I go along

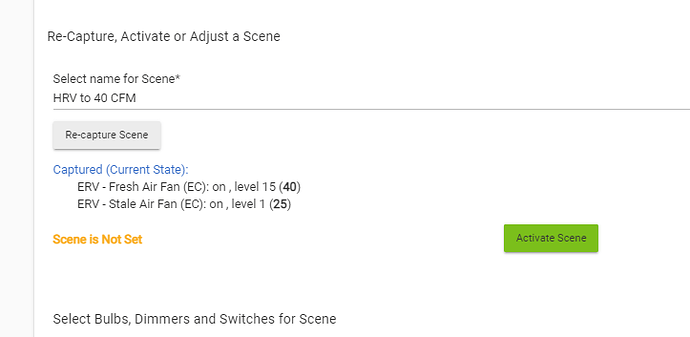

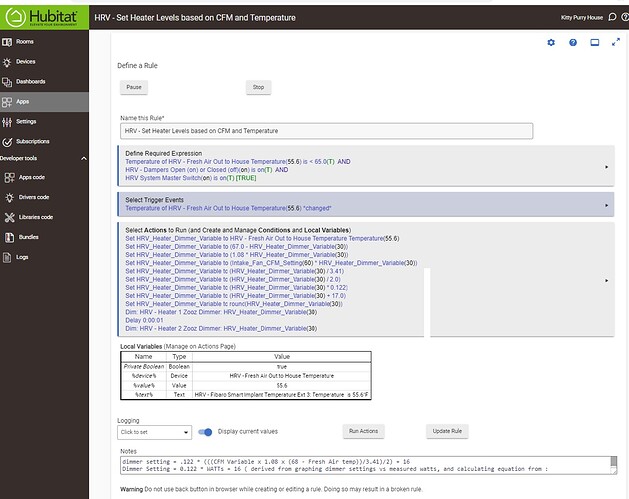

In Hubitat I've created several scenes like this one which set the intake/exhaust motors for balanced air flow. The intake has to work much harder than the exhaust due to the HRV core design, filtration, etc. Level 40 on intake with level 25 on exhaust (the current setting) works out to a balanced 55 CFM.

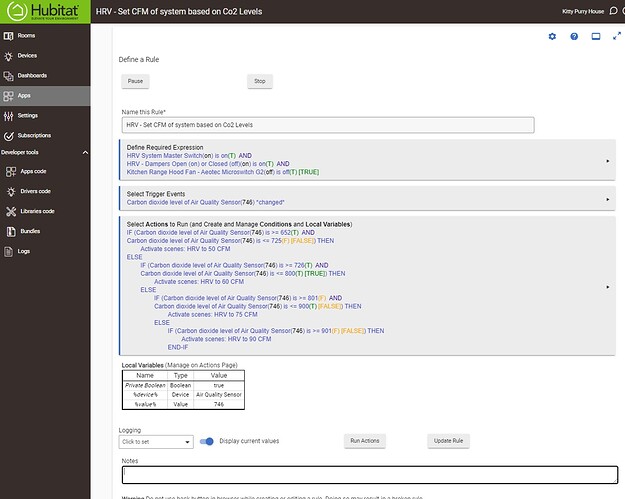

Fireplaces or wood burning appliances can be a challenge in a "tight" home, but controlling ventilation via ECM motor control means you can add some air for example when a temp sensor triggers an automation. In my case, I would ramp up the intake fan (so deliberately unbalance) the HRV to replace air leaving the home via the fireplace. This in turn can eliminate back drafting when you load wood etc. I have that exact scenario working now when the kitchen hood exhaust fan automation is triggered by the induction cook top (power use) detected.

Kitchen hoods, HRV/ERV, bath fans etc. only work when people use them...so automation can make a big difference in these situations to keep interior air quality where it should be.