Thanks, this might be what I'm looking for.

This whole setup is quickly becoming a bit much for my non-developer brain to keep a grasp on.

I ended up creating two rules each for three temperature "modes."

For each mode, I needed a separate temperature setpoint for on and off, I found that one rule with actions to turn the a/c on/off based on true/false for one temperature setpoint resulted in the a/c compressor cycling on/off too quickly.

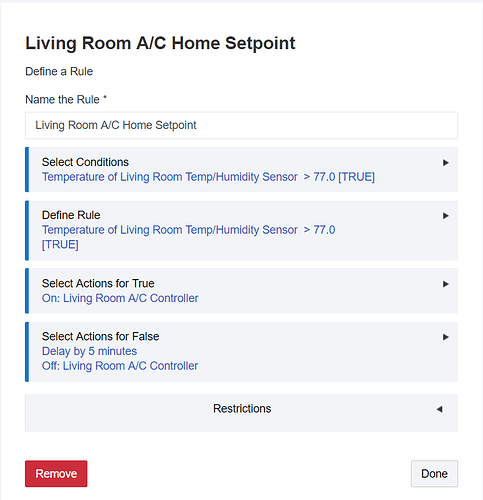

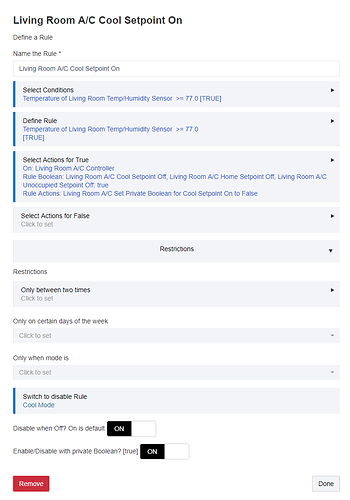

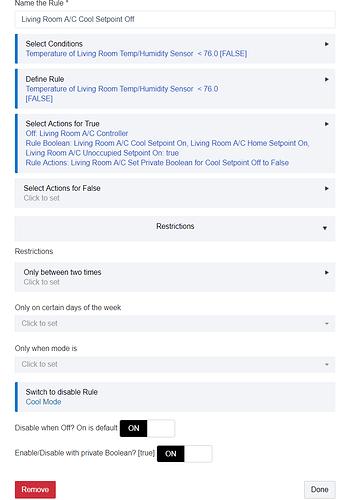

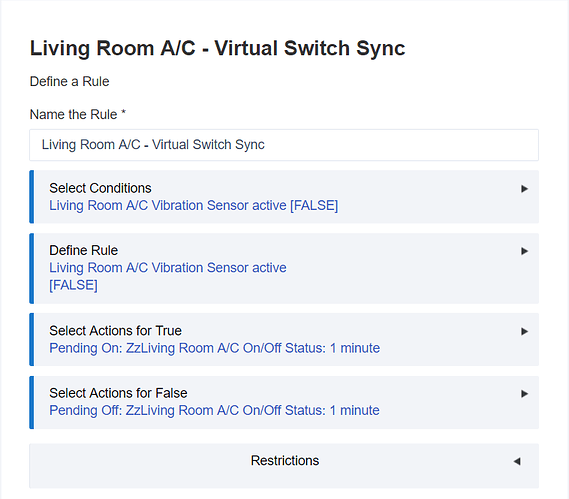

Each rule that causes the a/c to turn on or off has a switch and PB controlling it. Here are screen shots of the two rules for one of my temperature modes.

Turn a/c on

Turn a/c off

The disable with switch allows me to use dashboard switches to change between these temperature modes, I have simple lighting automations that toggle one mode on and the other two off.

My reasoning for adding the enable/disable by PB was based on the idea that once an "on" rule runs, it shouldn't run again until an "off" rule has run.

I have two other pairs of rules for the other two temperature modes, but they're basically identical to the screenshots I posted above.

As long as I stay in one temperature mode, it all seems to work fine. Where I've been getting into trouble is when switching between temperature modes.

I was finding that rules were executing at unexpected times, and I believe it's because they essentially "missed" an event that would have updated truth state while disabled. With a subsequent event that caused rule truth to be evaluated, a now-active rule ends up running and causing the a/c to get out of sync from what I intended (recall that the a/c has only a single IR code for on and off).

I appreciate your assistance with this, since I'm very much not used to thinking this way.

Does what I've posted so far make sense? Any thoughts on continuing down this route vs. starting over from scratch with a different paradigm?