They are good, but tbh plastic razor blades are better.

I have a few of those. ![]()

Do you print those or buy them?

And of course the best is having a perfectly calibrated printer and never needing to scrape... ![]()

Agree. That's what I use.

Did not even know these things existed...ordered a set for some window scraping I need to do.

been lurking here for a few because I have 3D printer envy - and as fool and his money are soon parted obviously im going to buy one sooner or sooner

anyway - cant help but do some internet research and I guess like everything the more you look the more you see once those search algorithms kick in...

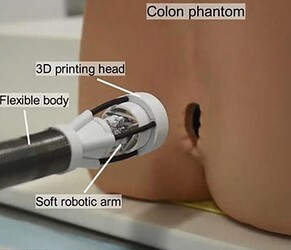

low and behold New robot enters the rectum to 3D prints living cells in human body (msn.com)

We look forward to you joining us in the 3D Printer Ward. ![]()

![]()

I dunno...that probe looks too big, even w/a "soft robotic arm."

Just cut me open instead. ![]()

Buy, they are dirt cheap on Amazon.

On the way!

so it sure looks / sounds like Sovol is a good bet -how does one decide between SV06 SV01 Pro and SV05

prices are $259, $289, and $289 respectively right now on their website

PS also feel like i need a laser engraver too! Any experience here with those attachments?

The main thing I've noticed is that there have been a lot less problems\issues overall reported with the SVO5 than the SV06 which are two of their newer printers.

Hard to say but it might be just that there are fewer users of the SV05. Mine has been pretty much been get it assembled & configured properly, and start printing with no issues that weren't caused by myself by my endless tweaking and changes of operating system controllers, you know like Octoprint and then now Klipper..

There definitely is more online activity overall around the SV06 in terms of forum activity on the Sovol site and other forums.

The main difference in terms of structural stuff is that the SV05 is Corexy and has a bed that only moves vertically in the Z direction and the print head does all the XY movements. The other two printers are bedslingers. When Derek was helping me choose he seemed to prefer the CORExy, at least for my purchase.

I guess one amazing benefit you'll get if you do get the SV05 is I can share all my experiences and information about using the printer and secrets of Octoprint and Klipper.

Out of those the SV05 would be my choice for sure. No question.

It's not actually CoreXY, but could easily be converted to CoreXY if you wanted to.

I have 2 bedslingers but at some point I'd like to build a non-bedslinger. The heavy bed becomes a major limitation when printing fast and is just not a very efficient system overall compared to a printer with a bed or gantry that moves in the Z axis.

It's also much easier to get a cube frame style printer square and keep it that way.

Thanks - I have to admit I'm a bit confused because I see it getting called CORExy in some forums and Cartesian in others. Not sure I really get the difference.

Can I just say "my printer lives inside a square set of rails? ![]()

It's a Cartesian Cube format printer with a seperate Stepper for the X axis and one for the Y Axis.

CoreXY printers also have 2 Steppers for the X & Y axis, but they are linked at the print head and work together to move the print head.

And I did not pay him (very much) to say that. ![]() Phew...

Phew...

Looking for a little help here.

Over the weekend I was able to melt out/clean the heat sink and hot end on my SV05. After reassembling everything the filament wont load past where the hot end and the heat sink. I can stick nozzle cleaning pin thing all the way through from where the filament loads to the end of the nozzle so I know its not fully blocked but seems misaligned.

What am I missing?

Did you re-install the small piece of bowden tube?

you mean the teflon insert on the hot end or where the tube connects on the very top?

The first option (teflon insert).

Btw, you could try removing the nozzle and use a 2mm drill-bit to remove any residue from the feed-in side of the nozzle - there may be crud still there.

Just to be absolutely clear...you use the drill bit in your hand kind of ram-rodding up and down as if you're clearing an old musket?