That's interesting.

My first gen Sunlu dryers have a small hole in the top that can be used for feeding filament.

Also doubles as a vent for escaping moisture.

That's interesting.

My first gen Sunlu dryers have a small hole in the top that can be used for feeding filament.

Also doubles as a vent for escaping moisture.

I always use gyroid. Would never pick an overlapping fill.

I just remixed a couple Prusa spool holders so they'll fit on the Sovol SV06 top bar (wish it had a 2020 extrusion embedded in the top bar) and will be using gyroid for added strength.

Is there any reason not to print everything in PETG, what benefit does PLA have over it? So many filament types…

Unless you have a fast core XY printer, gyroid is slower to print than cubic due to the constant direction changes.

If you have desiccant installed, this shouldn’t be a problem.

Mine has two holes for filament feed since it's a double spool unit, but evidently Sunlu thinks they are not big enough.

I have a basket I printed (that one I found) full of desiccant in the center of each spool.

Perfect.

The reason they say that is the moisture needs to go somewhere when the heater is on and making the Filament dry.

If you have desiccant it will absorb the moisture, if not opening the lid will let the moisture escape.

petg vs pla

"PETG requires somewhat high printing temperatures, which limits the number of compatible printers. Additionally, there are a few common printing and part quality issues, like over-adhesion and stringing, that make the material more difficult to work with."

To add to this, the current hot-ness in filaments is TPU, which is more flexible ...but not all printers can push a flexible filament into the hot end, apparently.

sovol dryer, petg

I'm lagging behind you on this. Dryer arrives tomorrow, Sunlu petg mid-week.

I've got two spools of PETG waiting for testing, but the printer I will be using (PEI sheet) is busy printing. Temp Tower is already sliced and ready to go.

I've heard horror stories of PETG pulling the coating off of glass beds, so I've avoided trying it on my Ender 3-V2.

The Anker came with pei sheets, but I've seen lots of chatter about laying a bed cover of painter's tape and printing on that.

True...PETG is typically used by zombies and space invaders! ![]()

Maybe better, to learn from my mistakes.

(Raises hand) Ah, professor, is this what you mean by over-adhesion? ![]()

Some significant PETG over-adhesion on first larger object (cup holder) so evidently I need to make some changes... ![]()

Other than the over-adhesion the print came out great.

Yikes.

Did that damage the bed?

Unclear if I can get it off or not. A little afraid to try, frankly. I'll see how resistant it is to some gentle scraping, but also thinking I may need to heat up the bed to get it off.

Would love some "Well when that happened to me I did this!" feedback from the more experienced here. Worst case I can just order another PEI sheet (this one was a Creality I got from Amazon).

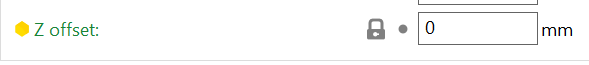

This Z offset below has been working perfectly for all my PLA prints, which I can pratically just lift off the PEI bed after it cool. Clearly not working for PETG. Not really sure what I should try next.

My setup for the print temps was 240 nozzle and 70 bed:

my mistakes

"PETG, however, often sticks too well, enough to tear out pieces of your printed part or build surface! As a result, you should always use glue stick or hairspray as a release agent and never print directly on something like BuildTak, PEI, or glass."

Did not see that. My first print using PEI was a calibration cube and I had one small area that stuck, but nothing like the big print of the cup.

So, poll of more experienced here, are all of you using glue stick, hairspray, etc. when printing PETG? I didn't get that impression, at least no one mentioned doing it IIRC.

I'm using the Magigoo dauber stick for pla. Love the stuff.