For your notifications, how did you set that up? I downloaded and installed the driver and installed a Klipper device. Did you use Rule Machine to set up your notification or something else?

Exactly this, the screen shot I posted earlier is my Rule Machine rule. If I get time today, I’ll upload it to GitHub for you.

Ok, here is an export of my RM rule:

Just import it into RM and change the devices to your printer and notification methods.

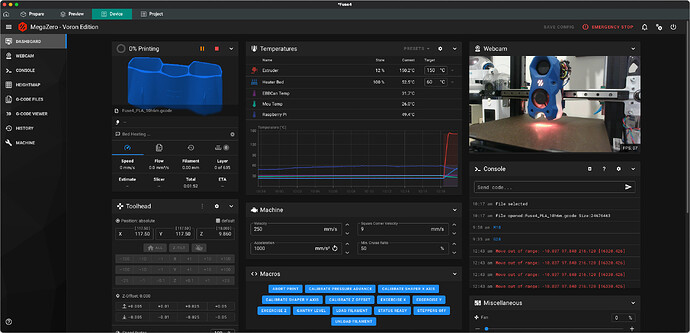

I use Mobileraker on my phone and installed the related companion software on my klipper host.

I run two printers off my single host.

That looks pretty cool, I hadn't heard of that.

OctoPrint & Windows: How to Get Started | All3DP

I finally got permission from the MoF to order a new printer, the AnyCubic Kobra S1 Combo.

I will of course be jail breaking it. ![]()

I’ve been wanting to try 3D printing a flying RC model aircraft for quite a long time, so when I saw this video on YouTube, I couldn’t resist and bought the design.

I’ll need to buy some RC gear and EDF’s too, but thankfully most of it is pretty cheap these days.

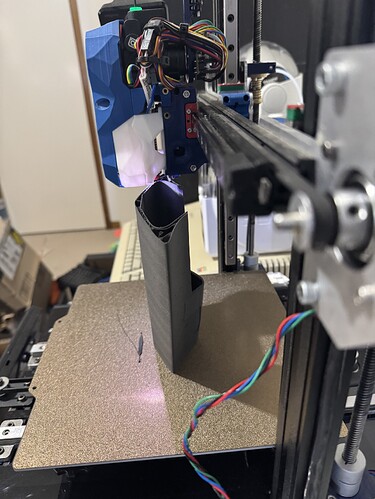

I managed a couple of test prints today and have the settings for eSun PLA-LW dialled in I think.

I was a bit eager taking it off the bed (which had Dimafix on it), and didn’t let it cool down - as a result I broke the bottom layers.

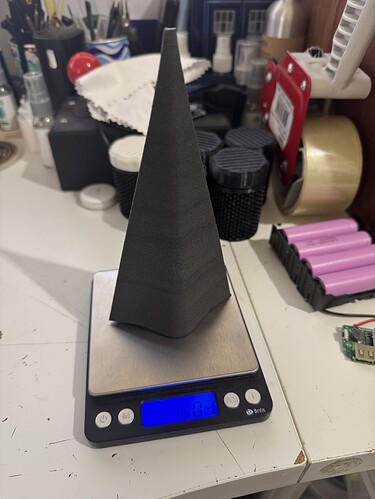

However, I’m very impressed with the result, it only weighs 6.03 grams!

I watched a gif-post about printing aircraft models with LW filament. They broke their 1st attempt, too.

I've also briefly seen some sort of foam-filled filaments being used for aircraft models (which looked to be a complete PITA even for the experienced makers).

I've also happened across some makers are using a 'trick' double-wall vase mode for the fuselage & wings

https://old.reddit.com/r/OrcaSlicer/comments/1hc9acd/double_wall_vase_mode/

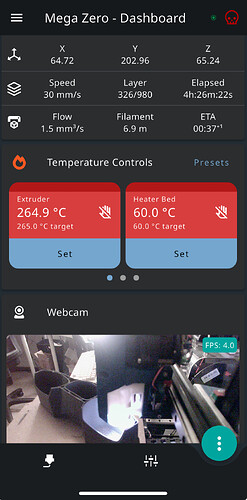

It’s actually pretty easy IME. This is what I’ve settled on after a little research and testing:

- 265c Nozzle

- 60c Bed

- Speed 40mm/s

- Travel 180mm/s

- Normal Accel 1000

- Outer wall Accel 800

- 20% Cooling from layer 4

- Flow ratio 0.45

- Retraction = none

- 1 wall

- 2x top/bottom layers

- 3% Gyroid

- Avoid crossing walls (no exceptions)

It does help when models are designed specifically for the material and prices tho.

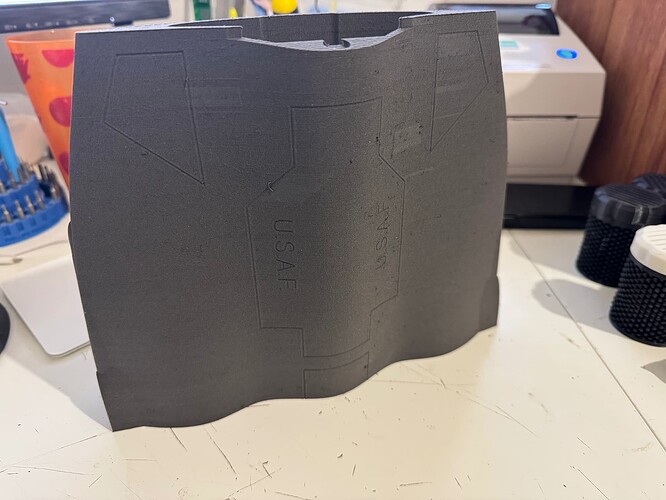

Btw, this is one of my earlier test parts. Word of advice, dont use a smooth PEI sheet with Dimafix on it…

Textured PEI with no bed adhesion additives is best.

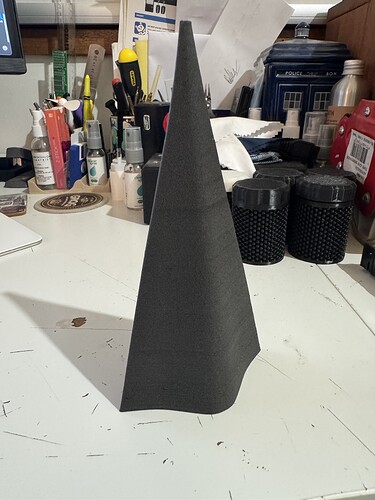

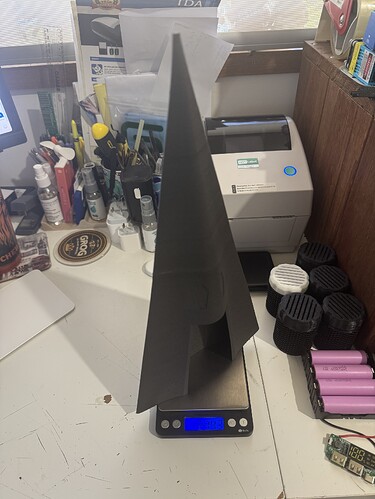

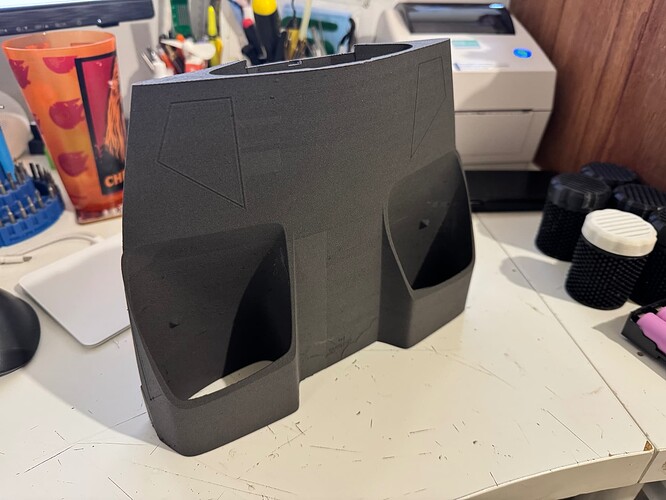

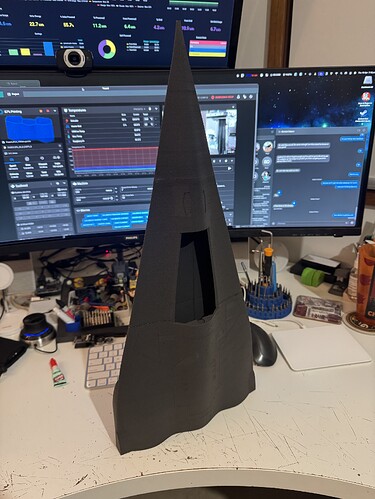

2 parts done!

Part 3 is a very long print! 40mm/s feels like cheap bed slinger speeds from 4 years ago!

This 10 hour print came out great! Although, I have discovered playing around in the slicer that using "Back" for the seam should produce a cleaner print, so I'll use that on the next part.

Now on to the next one..

It’s getting bigger! I’m using a gel type of super glue, seems to be working well.

Edit: another section complete.

My Kobra S1 Combo arrived today! ![]()

I’ve only unboxed it tho as I need to not overdo things still. My wife was unimpressed as it was that I hauled a 25kg box upstairs by myself when I’m not supposed to, well, do things like that!

I was very impressed with the packaging tho, it’s just very, very well thought out, and intuitive to unpack. They managed to fit the ACE unit inside the printer volume and use the same piece of moulded plastic to secure the ACE and the printer bed.

Aside from the plastic doors, the printer feels bet well built and solid. I don’t mind the plastic does tho, especially after seeing uncle Jesse break a glass door by accident.

Anyway, I’ll see if I have the energy to finish setting it up later this arvo. I’m very keen to print off my CNC pendant as the wheel and LCD also arrived today.

Congrats on the new printer! I took a look at that for a bit and compared the kobra s1 to adventurer 5m pro (both are dead even at $450 US right now) and was seriously considering the kobra, probably would have chosen over the 5m pro but cheaped out and just ordered the adventurer 5m for $279 it will be here tomorrow.

Full confession I had taken a lengthy hiatus from printing I got tired of futzing with my SV05 and I just put it back to stock and gave it away. I think I had too many self inflicted issues from over complicating things.

Not sure what I’ll do with BTT raspberry pad5 I was running Klipper screen with

Cheers. ![]()

I’ve got an Adventurer 3 and would never consider another FlashForge printer - everything was proprietary, and they wouldn’t give me any info at all. So I ripped all their stuff out and designed custom PCB’s to allow me to use Klipper with E3D Revo hot ends and a touch probe.

Yea that’s some crazy mad scientist stuff right there- I remember seeing your build early in this thread. I’m just not a heavy user - just single color PLA for odds and ends around the house. Hopefully this 5m will be reasonably simple and reliable ![]()