Being that it’s camping season again, I’m back to work upgrading my camper. This involves all sorts of those tiny wall box modules. The terminals on these are typically pretty small (16awg and smaller) which has me wondering about installation in a home where almost all wiring is 14awg and the balance is 12awg or larger. What is the (code-compliant) method people generally use to land 14awg wire on a terminal sized for 16awg and smaller? Of the instruction manuals I checked, they don’t make any reference to larger wire sizes.

I'm a bit confused why if you are working on the 16awg camper, why you ask about code-compliance for a house with 12/14awg?

Wouldn't you just keep everything 16awg for the camper, which will easily fit in the 14/12awg terminals on the home smart devices?

Working on the camper made me think about using these same modules (eg shelly 1), which are also rated for 120v applications, in a home.

I also just ordered Shelly wave 1’s (fingers crossed I actually get them) and they are also sized for 16awg but rated for 16a at 120v. Over the years I’ve seen many such modules that are the same. In fact, very few of these modules are dual rated for 120VAC and 12VDC - almost all are AC only… and a few that are also 24VDC.

So I was curious how people who install these modules in their homes are doing it in a code-compliant fashion.

Ah, that makes sense, it just wasn't clear in the initial post.

That seems odd. In homes, the standard is 15 amps on 14awg (lights), and 20 amps on 12awg (outlets). Those must be sized for camper wiring specifically, but they can handle 16a at 120v, given that your whole circuit supports 16a, including the wiring, which could not handle 16a with 16awg. It may also be to account for the inrush current when LEDs start up.

I would use them only for lighting in the house, and use 14awg, if you can figure out how to get it to fit. Or, if your load never goes over 10amps, you could splice in some 16awg to make the connection at the switch, and then be sure to put a 10amp breaker on the circuit instead of a 15a to protect the 16awg wire that is spliced in.

Even in 2023 NEC, which allows 10A circuits, the minimum wire size is 14awg - at least that’s how I read Table 210.24(I). So still unsure how this is legal. The new Shelly wave 1 US UL is “UL Approved”, but still lists the max wire size as 16awg. I believe many of these wallbox switching modules are similarly sized for max 16awg.

I assume that refers to the full run in the walls from the box. I'm talking about a 4 inch splice at the switch inside the switch box. My thinking is that there are some switches that come with wires attached already, and you connect them with wire nuts in the box. These switches certainly do not come with 14awg pigtails, and they don't even suggest to use a 10a breaker to protect them.

So I'm not sure where in the code a 16awg pigtail inside the switchbox comes into play, but they do make switches with pigtails less than 14awg rated at 15a or more.

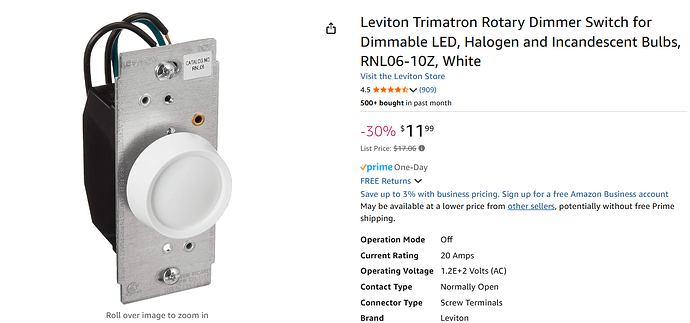

Case in point: look at this dimmer. It is rated for 20A. It is using 18awg pigtails at the switch.

I don’t believe anywhere in the code allows a field installed 16awg pigtail on a 15A ckt, or even a 10a ckt - at least that’s how I’m reading it. The code does allow listed devices that include undersized wires - as long as they’re listed by a recognized authority (depending on what the AHJ recognizes).

Google AI:

"20A switches often use 18AWG pigtails because the pigtails are designed for short lengths and low current draw, which is typical for the internal wiring within a switch or device. While a 20A circuit requires 12AWG wiring to handle the full 20A load, the pigtails within a switch only need to handle the switch's internal current requirements"

Which makes sense, most circuits feed several loads, but each individual load does not represent the full circuit load requirements.

However, another search about being "code-compliant" gives the opposite answer.

"Pigtails, which are short lengths of wire used to connect devices to the main circuit wiring, should have the same ampacity as the main circuit."

So I don't know what to make of that. It really all depends on the load going to that individual switch, not the whole circuit. If you are not going to have this work inspected, code doesn't come into play, except for your own safety. If you do not overload that individual switch load specifically, you should be fine. You can ensure that by using a 10a breaker on the whole circuit, as that will protect the 16awg pigtail for sure. It would be technically unsafe to use thin pigtails and not protect them at the breaker level, though many people do, in case a larger load is ever attached to that switch in the future and the pigtails are still there.

You know how many amps the lights you are attaching to the switch will take, if it is less than 10a you are good with a 16awg pigtail. Depending how many other things are on that circuit, a 10amp breaker may not be enough when all the loads on that circuit are on at once, so that could be an issue with using a 10amp breaker on the circuit.

Edit: Think about things you plug into 20amp wall outlets, that are wired with 12awg from the breaker. Are the stranded wires going to the fan or whatever device 12awg? Usually not. The wires on any individual appliance that get plugged into outlets are only rated for the amps the device consumes. What would the difference be in using a lamp plug wire that is not 12awg? Is that not just a long pigtail going to the the lamp switch that is less than the rating of the circuit?

You could use an insulated pin terminal connector to fit the 14ga wire into the Shelly's smaller terminals

Now that sounds legal!

Not sure why I didn’t think of that - we use those for large feeders - I guess I never thought about them being used/available for small wire.

Except for the 16AWG side of the pin is still 16AWG, so it is just a short pigtail and ultimately has the same resistance as 16AWG wire for its length, maybe even less based on material.

" A 16 AWG pin and a 16 AWG pigtail (wire) will have the same resistance per unit length"

A half inch vs 4 inches length will not make much difference here. Maybe if you buy gold or copper pins, but aluminium pins will have a higher resistance than the copper wire pigtail.

You be you, but I think you are overthinking this at this point, and that 16AWG pin is not going to be any "more legal" than a short 16AWG copper wire pigtail.

But the difference is these are generally listed for the application. So legal.

I don’t think this is a matter of overthinking. The original post was a simple one - what is a code compliant way to do this. A pin-terminal adapter is generally legal - an undersized pigtail (that is not part of a listed assembly) is not.

Legality only comes into play when a licensed contractor does something with the wiring in someone else's house. Anything you do to your house in your walls is not "illegal", though it may be a safety concern. The fact of the matter is, this is not a big risk, and the pin vs. wire is such a small difference it doesn't really matter at all.

Use the pin or a pigtail, don't tell me one way is inherently more "unsafe" than the other, as they are practically identical, and neither are "illegal" if you are doing it in your own house.

I would disagree with this statement - as I imagine an insurance company would… and definitely the AHJ. But I really don’t want to get off the original topic - which is not about safety, and not about the freedom to do whatever you want in your home - it’s about code compliance.

If I install any device or do any work in my home, I ensure I comply with applicable codes. I put a lot of work designing my home - electrically, architecturally and otherwise… so why deviate from code compliance if I don’t have to? Also, I absolutely worry about the insurance aspect - I realize the risk is almost zero, but if I can eliminate the risk entirely, why not? Finally, I work in the electrical trade - I’d be embarrassed to install something non-compliant - especially if there’s a simple solution to do it in a compliant way.

Edit: by “legal” I mean code compliant. That said, the AHJ will typically expect that whether you or your licensed contractor does any sort of renovation, rewire, etc, it shall comply with all applicable codes.

Ok, I agree with you, screw up and it is a liability for insurance. People do incredibly stupid things with wiring in their house, usually just with extension cords and powerstrips, not to mention leaving bare wires spliced together, and such, without even getting into wall wiring.

But AHJ do not do random safety inspections of homes. I did a major renovation DIY several years ago and re-wired everything myself from scratch without a need for an inspection.

We ended up having to actually tear down and rebuild 1/2 the house for structural issues (old). I worked with my contractor to let me come in after dry-in, and I wired the rebuilt section (Kitchen, Dining, LR) from scratch, including burying the service line myself and connecting it to my house. The power company met me at the appointment, I had the cable coiled out by the pole. They pulled the meter and let me unhook my old service cable at the breaker coming from the overhead line, while they finished putting the conduit and cable up the pole and connected it. I connected the new service cable to the breaker, coming in from the new meter box I installed, and then I gave them the go and they put the meter on the new box to turn power back on. They locked the box and left, no charge or questions.

I had a friend I worked with at the time who was a licenced electrician. I read through the manual and picked his brain for weeks before doing the work. I saved thousands of dollars on an electrician, because this was all in my home, and it was all legal because it was done by me, in my home. I am confident I did everything to code, however, with my "mini-apprenticeship" by having an electrician to guide me and answer every question I had.

In Vermont, no inspections are needed for any electrical work done by the homeowner, at all. In my town, I didn't even need a building permit to tear down and rebuilt half of it since I didn't change the footprint. The bank financed the rebuild, without needing an inspection of any of the work, including mine, because that is law in Vermont.

So, you can see why a debate about a 16awg pigtail being "legal" vs a pin just seems like overthinking it to me at this point.

I had a feeling you must live somewhere that allowed unpermitted work.

Here in Northern Virginia, homeowners/contractors are generally allowed to do one-for-one fixture/device replacements without a permit, but that’s about it. Regardless though, the applicable codes must still be followed no matter how small the installation. But you’re right, nobody’s coming in my house to inspect.