I'm late to the party, but assuming you bought the T6s, I'm curious what you think of them?

I have three T6's but I found a few issues with them after using them for a bit.

-

Temp is in Celsius, converted to Fahrenheit. This means the F display can never show certain temperatures, like 71 F, due to rounding. 21 C rounds to 70 F and 22 C rounds to 72 F.

-

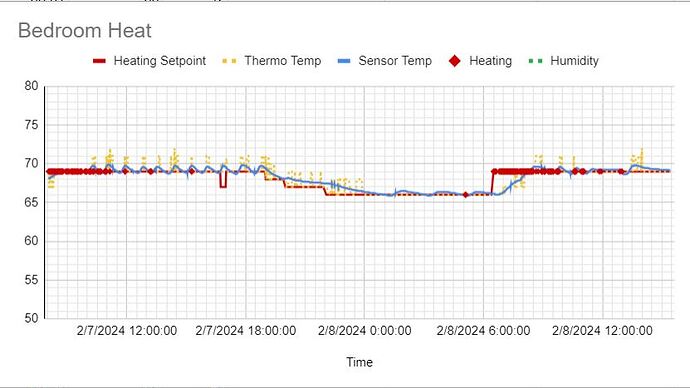

No hysteresis setting! I have baseboard heat so it is delayed after it comes on, and continues after turned off. The default hysteresis is two degrees, I believe. My house was swinging at least two degrees either side of the setpoint, so a four degree difference in temperature overall between cycles. It was very noticeable and annoying.

I solved the hysteresis issue by using a custom virtual thermostat driver and a custom T6 controller app. I took advantage of the temp calibration feature as an attribute in the T6 driver to control the thermostat turning heat on and off, with the virtual thermostat in real control, and allowing me to use a custom hysteresis. I have to bump temp cal up until it turns off, and down until it comes on, and check every minute to keep things in sync. Settings changed on the physical T6 are synced over to the virtual thermostat.

That worked OK all last winter, but it was a bit clumsy, and when using remote temp sensors I cannot always adjust the cal enough to keep it off if it is in a colder area than the sensor. So, I took control away from the T6 entirely using a ZigBee relay module instead to control the zone valves and furnace. The thermostats sync with the virtual thermostats, so they are basically dumb interfaces now, still using a common wire to keep them mains powered.

Besides custom hysteresis, I added other features. One is showing heating by increasing the screen brightness to full, and idle with brightness to low, since these also do not show heating status on idle screen. The fact that screen brightness can be controlled through an attribute is a nice feature of the T6 driver! I also use it to turn the display off at night in the bedroom, and to turn it on bright with motion to provide a nice dim light if I get up at night.

I added the ability to use multiple remote temperature sensors. I also added using motion sensors in the rooms to activate what remote sensor to use for setpoint, so the setpoint will follow you to the room you are using. Now that I am using the relays, I now use the cal feature just to make the thermostat display the temperature of the remote sensor. The apps reverts back to the old behavior if I switch back to thermostat control.

I also added options for a pre-heater device, so I turn on the electric fireplace heat for a bit when heat is called while waiting for baseboards to heat up. I also added a fan device feature to run the fan in the bedroom to circulate heat, which uses a delay setting to wait for the heat to come up first before circulating, and a delay at off to keep circulating the heat for a bit after.

I also added a 2nd relay board to re-engage the thermostats automatically if needed, like if the hub or a board dies on a cold day. The boards are wired to just default to using physical thermostats if there is no power to the boards or they fail. I use one of the ZibBee relays to remotely switch between using thermostats or the ZibBee relay control, since the board has four relays and I only have three heating zones.

If anyone is interested in this overly complex way to run your heat and fix a few issues with the T6, I can share the driver and app code, as well as a wiring diagram and the boards I used. I spent about $50 for the two boards and some bus rails on Amazon. Both boards run off the 24V AC furnace transformer, so no external power source is needed.