Wanted to share my recent project with HubDuino! I have a Mighty Mule driveway alert, but needed to integrate it into HE. Searched the forums and found this:

After watching that vid, I opened mine up and did some testing. Found that pin 11 is for the battery low indicator, and pin 12 is for Visitor. It is TTL output (5v). I soldered on a 3-pin plug and drilled a small hole in the case to pass out the side.

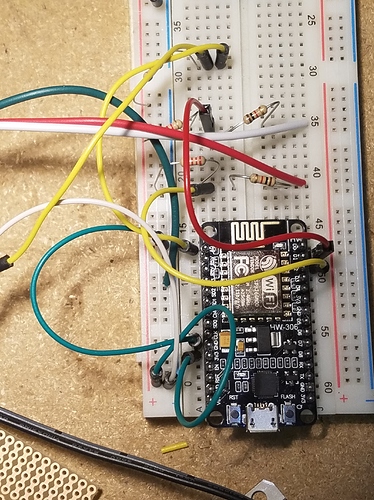

I used a simple voltage divider to connect these to D1 and D2 of a NodeMCU. (Gnd -- 2,2kR -- Input Pin -- 1kR -- TTL output)

I made D1 and D2 Contact switches. I am also using A0 for a 10k thermistor that is going in my freezer.

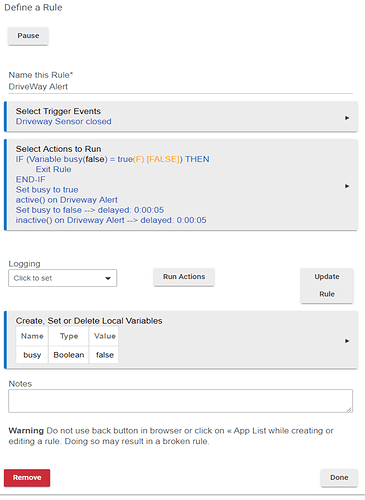

I created a virtual Motion Sensor and a Rule to trigger it:

Next step is to get audio announcements integrated into my ancient NuTone intercom. My plan is to use another HubDuino and this tied to the Tape input: Adafruit Audio FX Mini Sound Board - WAV/OGG Trigger - 2MB Flash : ID 2342 : $14.95 : Adafruit Industries, Unique & fun DIY electronics and kits