Getting magnets is easy, but my Iris sensors won't respond to a magnet unless the orientation is correct... a disc magnet has to be turned perpendicular to register. I can't just put a stack of magnets next to the sensor.

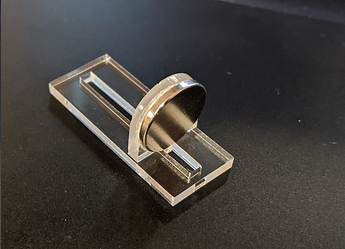

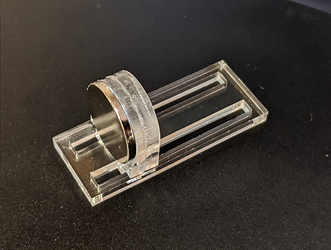

So am designing an L-shaped magnet holder with an adjustable position, and I think it will work, but it's kind of big and ugly and I don't love it. These magnets are 0.60" across, they are what I had on hand, but if they were a lot smaller then I probably couldn't shrink the design to match. The laser cutter can only cut parts so small, and small bits of acrylic are brittle. (The track length can definitely be cut down which will help, but these prototypes were designed to bridge a gap on my freezer door, hence the 1.5" length.)

If I do use these, the track will be treated with some super thin 2-sided adhesive. Once the magnet position is tuned in the track, a drop of glue will make sure it doesn't drift.

But I can't help but think I am making this more complicated than it has to be. Then again, in this community, I am probably in good company.