They have three chambers to fill the hot end so you get more consistent extrusion and, potentially, a higher flow rate.

Yeah, I really dig the outer finish with their CF filaments.

I got some PLA-CF spools when they were super cheap for their one year anniversary. I've only printed a couple test swatches to see what the finish is like, but it does have a nice texture to it.

Now I need to go find something to print with them ![]()

Been trying to use up all my old ABS spools that are a few years old before they turn to complete garbage. Just printed a column mounted key switch holder for my parents golf cart, since the current key location is below the bench seat near the gear shifter. Added a little white 'key' inlay so I can remember which way the key goes in ![]()

Dang, that's sweet.

Forgot to add, hope you're putting that up on the Printables/Thingaverse sites, I bet other folks would love that.

I've never tried printing something that requires that kind of strength... I mainly make boxes for sensors, etc, so PETG or PLA.

I have a roll of ABS, but never use it (with an only partially enclosed Bambu P1P it would likely warp into oblivion anyway). I'm afraid something like CF is likely outside of my expertise/capability.

You're setting your aim too high. Almost everything I've printed with CF was specifically for the aesthetics of the finish ![]()

I print ASA and ABS on my open printer all the time. It’s easy when you know a few simple rules:

- minimise airflow in the room (i.e. no cooling fans or AC)

- turn nozzle cooling down to 15% with 20% max for bridging.

- print hot. For ASA I use 260c, ABS at 245c and bed temp starts at 115c for the first layer and drops to 110c after that

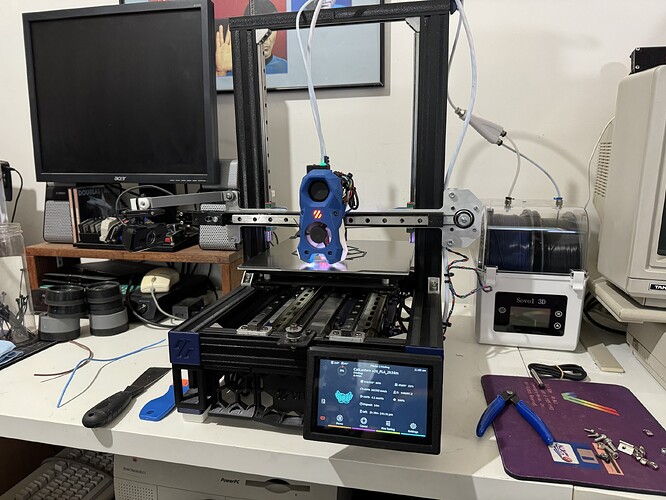

Every blue or white printed part on my printer was printed this way:

This is the secret! I don't even think my Anet A8 ever touched PLA, only printed ABS with it. It was a bedslinger, pretty much a knockoff Prusa. Towards the end of its life it actually lived in my office's small walk in closet, where my X1C lives now. It did pretty well in there, and after a few hours of printing with the door closed that closet got nice and warm. Typically if the bed stays hot enough, and cooling is low/off, it won't warp.

Once I use up all the ABS I want to get more PETG or ASA to replace it. I haven't printed ASA yet, but from what I have seen PETG is pretty much comparable with ABS, just not as warp prone. I believe ABS was around early days, before PETG was well known / widely available, so I think that is why it was much more popular than it is today. Though if you have PETG working, you're probably better off using that over ABS, at least it doesn't stink when it is printing ![]()

Yeah I probably will. Fairly niche product I assume (depending on what year golf cart), but it doesn't hurt to share. I'll wait until the fitment is confirmed, hopefully this weekend it will be on if all goes well. The key actually has two positions (accessory / run), which is nice if you want the lights / radio on without the motor controller active.

I find PETG annoying, it’s very prone to stringing and dropping nozzle pickups on your nice parts.

So I finally decided to get a Wash and Cure Plus from AnyCubic, because the 2.0 is too small for my Mono X.

Anyway, because I’ve had good luck and great support from their “seconds” store on eBay, I waited for one to come up at a price I was happy with. So the other day I grabbed one for $150 Aussie micro peso’s.

And today it arrived…… except it’s not a wash and cure plus, it’s a freaking Mono M5s 12k printer! ![]()

I’m so torn as to whether or not to tell them and see if they’ll let me keep it or whatever. Ideally I still want the wash and cure plus, but now I have this printer, I want to keep it! ![]()

Just to be sure we're all safe, you're absolutely positive your wife is not reading this forum, right?

Yep, we are safe and she has no idea that I bought the wash and cure, luckily the M5s came while she was at the office. ![]()

Thin ice, mate, thin ice. ![]()

![]()

And she also pays no notice to my stuff in garage and likely has no idea what most of it is. ![]()

"What, those? Those are all yard tools, honey. Look, I just got this nice leaf container."

Says Derek holding up his two-spool filament dryer.

![]()

My wife and I have a bit of a goofy hobby game going.

She buys yarn for crocheting (even though she already has bins of it) so I buy 3D printer filament, or accessories.

Sounds dangerously expensive ![]()

So overall, this printer is in much better shape than my Mono X was. The LCD looks great, a little resin has got under the screen protector, but not onto the LCD.

And it only has 14 prints on it, most of those were successful according to the logs. I think the last one failed due to the mess I found on the build plate. I assume the first layers were overexposed.

However, after spending 30 mins wet sanding the resin off, it looks serviceable again.

There are a couple of small dings on the chassis, but nothing serious. I think I’ll sell my Mono X if it works ok.

Very pretty...nice sanding job on the build plate. Thinking of so many chores you could help with once I convince you to visit. ![]()