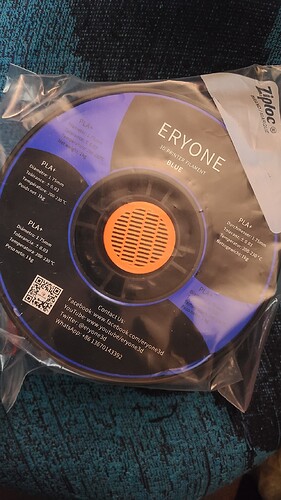

If that’s their Matte colour range avoid it, it’s trash. I bought some when it was on sale and it’s terrible.

PLA isn’t as bad as PETG, but can still absorb moisture, PLA + is worse that regular PLA.

I do pretty much the same, I store the spools in zip lock bags with descendant in their Shipping boxes when not in use.

For PETG I keep them in “vacuum” seal bags using the eSun vacuum kit.

I like abs + for structural prints and it doesn’t absorb moisture. So I just leave it lying around.

Same, so that means I can use a similar setup, I think I'll look into that.

Thanks for all the details and links, very helpful. Gosh darn it I'm going to have to buy more stuff! ![]()

![]()

I have vacuum seal kit and bags I use in the kitchen, so that could work out very nicely for me too. And of course I'll hide all the purchases of additional vacuum sealer equipment under the food supply label. ![]()

I plan to switch to abs as it is strong, heat tolerant, and uv-resistant. I've read that PLA can deteriorate within a year or two outside and it is brittle. Some say that pla objects can even go soft in a hot garage and I can confirm that it doesn't take much to severely deform it in the microwave. On top of that, abs has a strong, fusing glue available while pla doesn't do to well with many glues.

The downside of abs filament is that it stinks while printing. I'm working on an activated charcoal filter attached to an 80mm fan.

You're going to need a gram scale to estimate how much filament is remaining on a spool. I stole my wife's kitchen scale. Shhhh!

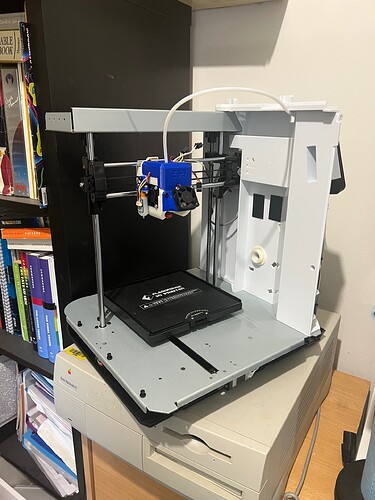

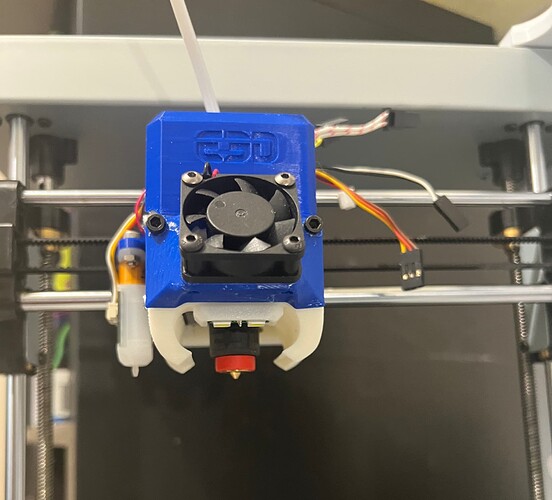

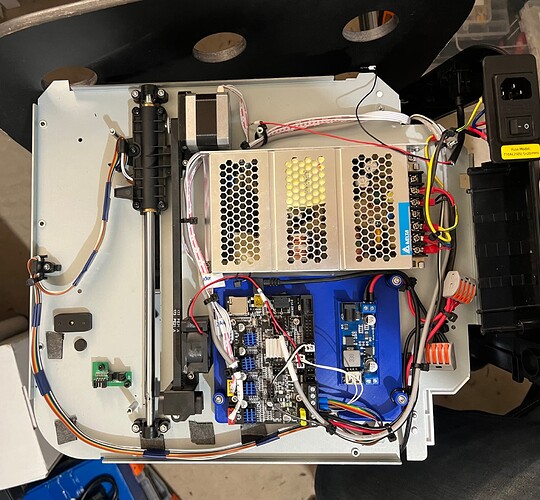

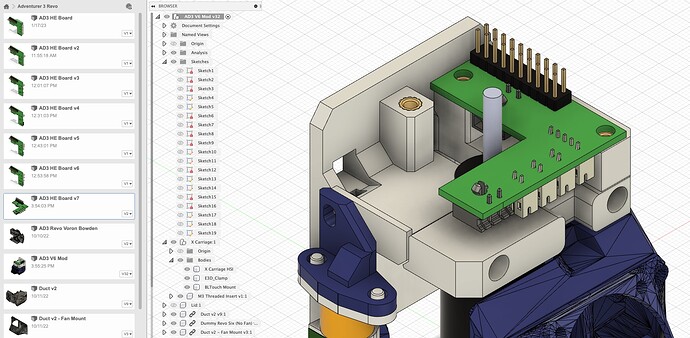

True, that's one reason I've been rebuilding my Adventurer 3 to be an ABS machine running Klipper - it's fully enclosed and has a chamber ventilation fan that I can put a filter over. I ripped out all the proprietary flashforge crap and have been rebuilding it from bare bones, including a new print head equipped with a Revo Six and BLTouch.

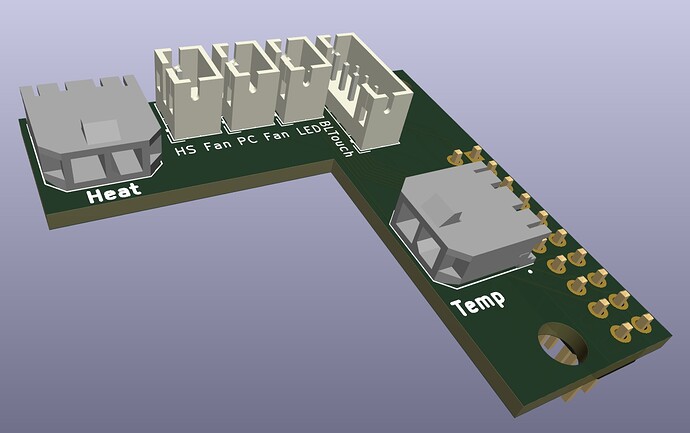

It's been a pretty challenging project, but fun. I even designed a new Hot-end PCB for it:

We live in an area that has really high humidity levels in the summer, to the point of usually not being able to print much between July and September. We don't have central air either.

Additionally, my printers (Ender 3-V2 with Sprite Pro extruder and a Sovol SV06) and filament are in the same room as several of my aquariums (why have one money sucking hobby, when you can have two?  )

)

I 3D printed desiccant containers that fit in the centre of the spools (fill with rechargeable Dry N Dry), then place the spools in a ziploc bag, then place the bag in a gasketed storage box.

Humidity here is usually high (96% right now). With hvac and dehumidifiers, it is a struggle to keep the interior at 50%. I'll use your method for long term storage.

I started making one of the 2 PCB’s I need for my Adventurer 3 rebuild. However I screwed up the inter track spacing. ![]()

Gosh, I hate it when that happens...oh, wait, I've never made a PCB.

So what about PETG vs. ABS? Asking since I can't do ABS (no enclosure), though I suppose I could move my printer out into the garage to print w/it.

Is ABS better/easier than PETG?

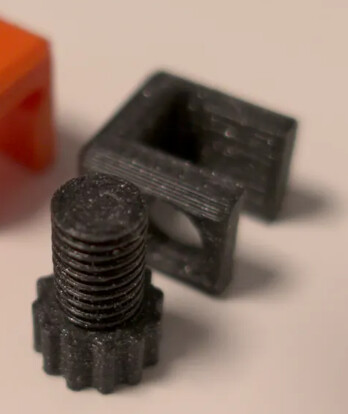

Quite impressed by a tiny print I did last night...very small filament clamp for spool. Really just printed it to see if it would actually work.

Caveat - I had to use pliers and a fair amount of force to get the screw to screw into the housing the first time, but after that it opened closed smoothly. Quite impressed that my cheapo printer could create the tiny thread w/such accuracy/detail. Below is from the Printables page, don't have a pic of mine:

I printed 4 of those at first and was also impressed with the thread. I've now printed some 8m threaded rod & nuts which seemed impossible --but they worked fine.

When I actually tried to use the above clip inside the dry box, it felt cumbersome. I'm going to try these;

Grandma's Favorite Filament Clip

https://www.printables.com/model/24371-grandmas-favorite-filament-clip

Funny - I also found that and thought it looked like a better option.

There is also this one, which looks interesting:

Dumb, good, or neutral idea to combine objects in a single print?

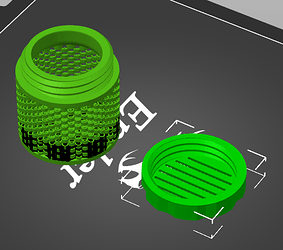

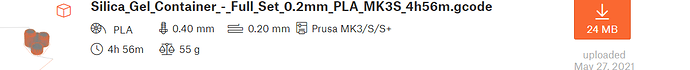

I'm printing a dessicant basket and lid from Printables, and rather than have to do two prints, would like to get this done in one job...

These two parts, small basket and lid, they are provided in separate STL files which I've combined here in PrusaSlicer:

He has the full set in gcode, so I figure just printing the two should be fine, right?

I do those two at the same time. Where I have trouble with groups is when some items are small --significantly smaller than the larger items in the group. The small item adhesion fails, and it gets pushed into the others, dislodging them. The 1st layer on both desiccant basket pieces is flat and broad, so they adhere pretty well.

Ah, yes, I hadn't thought about that potential for dislodging. I started the basket & lid print and it appears to be going OK.

I also did "Grandma's clip" - simple 9m print, very nice, and am going to print the other larger one ("Simple Filament Clip") and see which style I prefer between the two.

Next time I think I need to move the two pieces farther apart - right now it's doing layers on one and then switching to layers on the other, keeping them even.

Question about making prints of multiple objects faster:

- If I move the two objects far enough apart on the bed so that the head can print one w/out coming into contact w/the other, would the printer print one at a time rather than moving back an forth between all the objects on the bed?

If that's true, it seems like the overall print time would be reduced as there would be only one instance of travel back and forth between the two objects. Not sure if that would be noticeably faster or not...

From what I've read, I don't think moving them apart will enable sequential printing.

The article you pointed to seems to be saying that (at least in Cura) it is possible to print sequentially. Am I mis-reading, misundestanding?

The print one at a time feature, also known as sequential printing in other slicers, is in “Special Modes” under the “Print Sequence” option. In that option, there’s either “All at Once” or “One at a Time”. As the name suggests, “One at a Time” instructs your 3D printer to print one model at a time if you’ve imported multiple models (or duplicated the same one) into the build space on Cura. This feature is super useful if you want to print multiple models but need one faster than the others, and also to avoid stringing or other retraction-derived issues that can be caused as the print head moves between parts each layer.

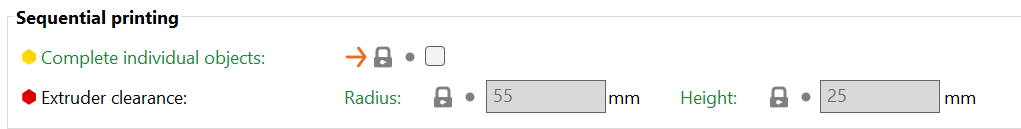

And thanks to the article I found the setting in PrusaSlicer: