Hobbyists can download Fusion 360 for personal use here by signing-in or creating an Autodesk account.

See, I went down the JOAT (Jack Of All Trades) route when I bought my Snapmakers... but I still really just use the 3D printing capability. Such a slacker...

Supposedly, the LowRider can be set up to cnc a full sheet of plywood or -maybe- 12 foot lumber. That's my real interest in pursuing cnc.

Added:

What I REALLY want is a 3dP for concrete!

There’s a free version for hobbyists that is 90% feature complete.

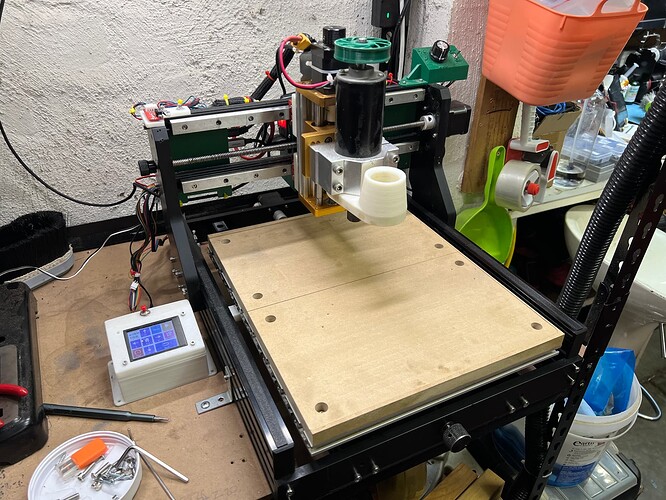

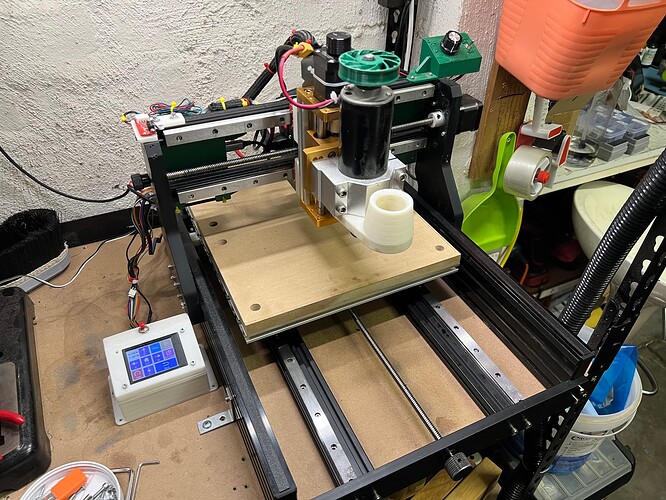

I built my own little CNC machine, it was a fun project. Set some point I may change it to a moving X gantry, but for now it does a great job.

Every time I think I'm doing something cool, guys like you, @rcjordan, @snell, etc., make me feel like a 3rd grader. Grrrr...

Somehow totally missed that, thanks for pointing that out.

No worries, here is a really excellent tutorial series to get you started.

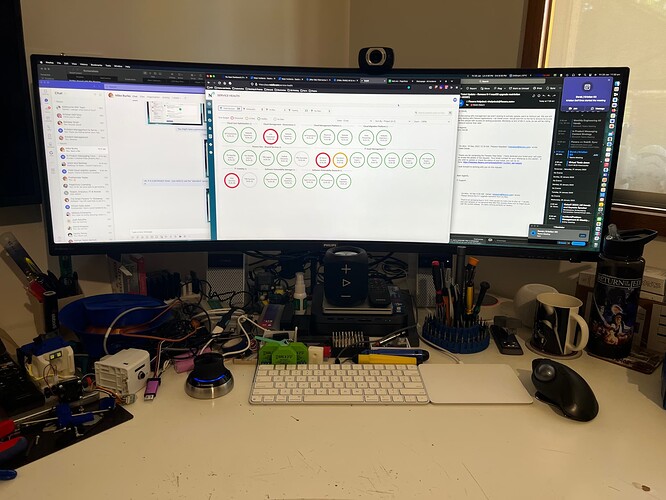

Btw, once you get good at 3D modeling, I expect to see you adding a 3D Space mouse to your workstation! ![]()

Thanks for the vid link.

Regarding the Space Mouse (superhero, and friend of Space Ghost?) - as soon as it arrives (you're sending me one, right?) I'll set it right up!

I see we use the same trackball --which I find to wiggle a little bit when working with close tolerances. What advantage does the SpaceMouse buy me?

I'm really hung up between getting the Sovol or just going full tilt with the Bambu X1 carbon. Someone make up my mind for me!

Go for speed.

It frees up your primary pointing device from navigation duties. This guy uses one for SketchUp, but the use case is the same.

I find I do need to clean the PTFE supports once a month or the ball stops rolling smoothly and this affects accuracy.

If you can afford it, it’s a no brainer!

IIRC, the Bambu won't use cardboard spools. If so, that'd be a big negative for me as I'm using Overture and beginning to experiment with cheap ($15) pla.

I saw that but also saw that there's some banding you can print for the spools to make them work.

My main appeal to the X1 isn't even speed...it's the enclosure/air filtration.

In the end, it'll be about speed. Even at 250mm/s these things are tooth-grindingly sloooowww.

There’s 3D printed spool surround to fix that.

https://www.printables.com/model/251028-cardboard-spool-ring-for-bambu-lab-ams-parametric

I've done similar ones for my dry box with roller cradles. Turns out, I can run without if I set the 608 bearings right.

Agree...even after only a week and just a few "real" prints that I've done for keeps, you quickly find this is a looooong waiting game. ![]()

Luckily I will likely never print so much that I'll have a big queue. (Or so he says now...)