Do you have anymore available? I would love to get one to play with.

Hi Everyone,

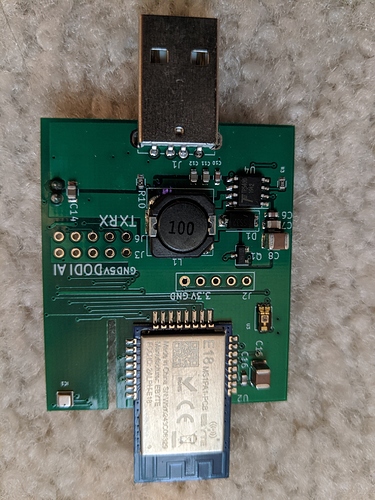

I just want to announce a new expansion capability for future build of Environment sensor. I am adding a serial port to the Environment sensor. The data from serial port will be tunnel through Zigbee to/from the Hubitat hub. I have a video about this new feature. My intention is to enhance the capability for all of use to expand the sensor to handle more complicated sensor using an external MCU.

Here is a youtube video interfacing with Load Cell and Dust sensor.

I will be sharing more exciting capability with the serial port in the coming weeks.

I am excited about he possibility that may be open up. I want to thank every one here who has supported my project.

@ogiewon, I have not forget about sending you a module with serial port access. I will send you one shortly for you to play around with.

Thanks

Iman

Have you printed this out to see how it would fit between your smoke alarm and the wall?

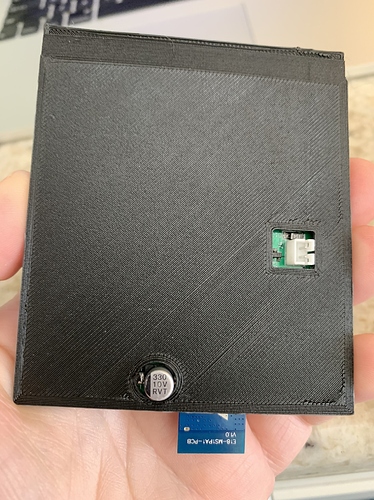

I printed the box and I don't think it's going to fit the PCB. Will need make it a bit bigger. I have the PCB coming so I'll design a new box to the correct size once I have it.

@iharyadi, please consider adding mounting holes for the PCB.

I will. The PCB for the bigger board with AC power has mounting hole on the original gerber. The PCB maker removed them. I have notify them about the issue. I will pay attention if I make this version again. Thanks for catching that.

Let me know when you design something, I'd like to use it as well for the unit I purchased. I may try to make a PCB protector to cover the mains connections and I’ll share if I make something usable.

Here is a protector I made. My thinking is I'd add screw points to this to connect it to whatever enclosure sits between my smoke alarm and the ceiling. Zigbee Protector v2 | Tinkercad. I don't plan on putting a battery into it.

Hi Everyone,

I hope you guys stay safe and healthy during this time.

I would like to announce formally a new functionality for the module. I am exposing a USART (serial port) expansion so that it can be interconnected with another MCU. This functionality allow us to add more complex sensors. Here is an example you can do with it.

I want to let everyone know that I have 10 modules available to share. This time I have the module assembled by a manufacture in a test run. The result is very encouraging. The yield is quite good. The build quality is much better than what I can do.

If you are interested on one of this modules, please PM me. Some of you have reach me before, I will try to remember you. However, please remind me if you can. I only have small quantity.

However, these are a test production run which mean that future availability at higher quantity is on the horizon.

I would like to take this opportunity to thanks everyone who has help on the project.

Thanks

Iman

I'm trying to figure out what units the pressure reading is in. I see in the driver code that kpa is listed but my sensor is reporting 84.6 which would be 24.98 inhg. That can't be right unless I'm in the eye of a hurricane and it doesn't look like it out my window

At the time I tested the sensor here before I shipped it, it shows ~100 kpa in Washington state.

Is it just one or all the sensor show 84.6? It is rather low.

Thanks

Iman

Just a data point for reference.

My original sensor is reading 101.9. And my second one is reading 101.8.

Just one, Iman. I'll get to the others tomorrow... hopefully. This is not an important reading to me as I don't see the need for pressure. I just like to check gizmos out and understand them. I"ll post a table of the readings from each board when I can.

Hi Steve, thanks for letting me know. I like to know it anyway. This batch is built by a manufacture. I am testing their yield. If this is a damage sensor, I really want to know so that I can plan for the future in term of yield.

I just did smoke test. I pair the sensor on my development hub. I looked at the values quickly to see whether they are unreasonable. I do not recall any of the sensors that I sent you have any strange reading. However, I could miss it.

If this is only one of them, I can fix it for you if you send it back to me. I can just replace the sensor.

Thanks

Iman

Thank you, Iman, but that won't be necessary. Even if I do decide I want atmospheric pressure for something I can simply use one of the others. It's not like it varies on my property. ![]()

Curiosity got the better of me so I got the readings from all the sensors. For reference, I put my ThermoPro base station close to where the sensors are plugged in and it says:

humidity : 34

temperature : 70.0

The pressure I got from the National Weather Service:

Barometer 29.7 in (1005.76 mb)

which equals 100.58 kpa

Note: I'm at 4700 ft elevation here

Readings from the device page:

# humidity illuminance pressure temperature

1 29.83 0.35 84.6 71.4

2 30.31 0.39 84.6 71.1

3 30.53 0.32 84.6 70.7

4 31.48 0.52 84.5 71.6

5 30.31 0.49 84.5 71.0

6 31.03 0.83 84.5 71.5

I don't know why the pressure would read so much lower unless the NWS somehow adjusts for elevation. My wall barometer is reading 29.5. At least they are consistent so I'm good.

Hmm, interesting. The pressure does not look like a sensor issue. I am around 550 feet elevation. I am reading around 99 to 100 ish KPa. Perhaps, your elevation of 4700 feet would make the pressure reading lower than expected.

The temperature reading is as my expectation. The Zigbee repeater is power up all the time. This will contribute around 1 degree Celsius offset. In the device page, there is a way to adjust the temperature if you like. I personally not do that.

Relative humidity has tendency to be reading low in the beginning. Eventually, they will settle down. The Bosch 280 may need to go through reconditioning process. They went through re-flowing after all.

The BME280 manual says "Ambient Re-Hydration ~25C at > 40% rH for >5d" is all that's needed after solder reflow. I'll see if I can setup those conditions. Thanks for the tip.

Update: Nothing has changed with the pressure readings but the humidity readings are coming around to match my ThermoPro. The longer a sensor has been powered up the closer it gets. This is without doing the

So I'm happy ![]()

Hi Steve,

thanks for the update. The reconditioning process can naturally happen based on my experience. The datasheet does have specific recommendation which I do not follow. I still see that the sensor humidity is re-calibrating.

Based on my experience, It also rarely hit to exact measurement to a reference device. There will be some offset. However, BME280 is known to have low drift. Therefore, once settle down, you may want to set the offset. The sensor should track well over time.

I have done some googling about the pressure sensor. I am not 100% sure as I only get fragment of information. There are some data that with 4700 feet elevation, the reading for pressure measurement is around 85.9kpa. This is not only source. Another example is here. The elevation does impact the result of the measurement. If I have a chance to learn about the pressure and its relation to the elevation, I would share more. For now, I think that the sensor could be reading a pressure value that is different from your other devices.

Thanks

Iman

Good info! Thanks yet again

I just want to update for those who are following this thread that I made a new variant of this project.