Like many of us with MYQ garage door, I am affected by changes in their cloud that caused the MYQ integration stopped working.

I found a solution inspired by some member here to take MQY integration local like the following thread.

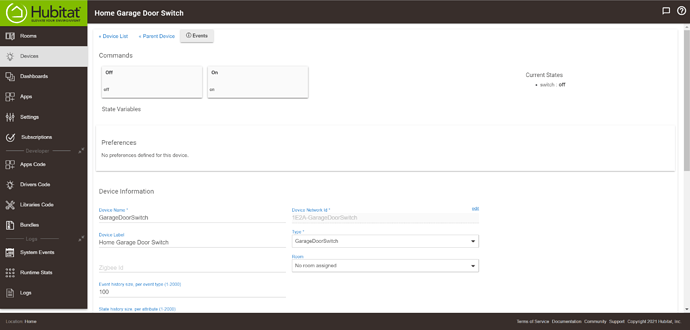

If you have time to go through the above thread, you will find lot of good and detailed information to solve the issue. I personally picked a solution that simulate button press using an existing remote. A switch device in hubitat will be created to represent the button. Using this switch device, you can follow the thread there that there are sets of applications that you can use to complete the solution that give you a garage door device.

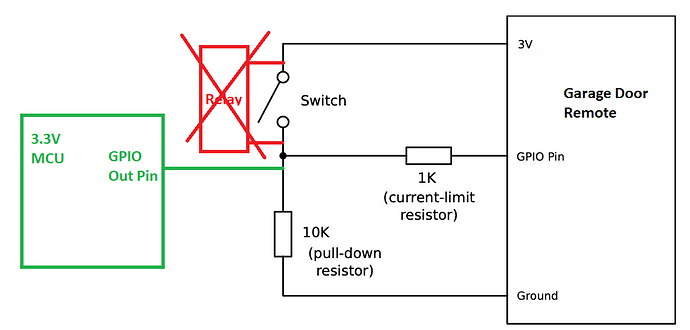

What is unique with what I am doing with the switch is that I want to eliminate the need for a relay. Most of the solution presented in the above thread require a dry contact relay. Eliminating the relay is possible since the button on the remote is a typical GPIO mechanism. Based on my understanding, the button roughly is as follow.

The idea is just connect a GPIO output from a 3.3V MCU straight to the button GPIO pin of a remote. This should have the same effect as shorting the switch to the 3V source.

Another twist that I did is to remove the battery and power the garage door remote from the 3.3V source of the MCU. The voltage difference is so small It would not break the garage door.

Here a prototype using the Environment Sensor digital output to test the ide. You will see that there are only 3 wires needed for power and a single gpio.

The switch will look like below.

Just FYI, this is just prototype to share my idea. My plan is to use an Arduino as expansion to the environment sensor. One of the reason for this is that the remote control has 3 buttons that I would like to take advantage while the Environment sensor only have one. With Arduino, I can have access to a lot more GPIO. There is also technical reason where I would like to have the Arduino to handle the button toggling rather than involving the hub. I also have plan to integrate additional sensors that would make sense for our garage door.

At this point, I just want to present an alternative which may be simpler for some of us.

Thanks

Iman