I built my MK4 from kit. Took a few days but it was super easy to do. Printed perfect first layer on the first attempt. Even I was suprised.

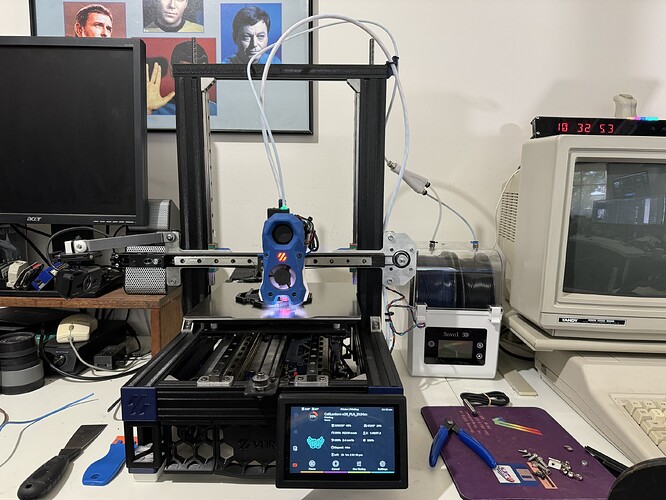

I don’t mind kits either, heck my 3D printer only has the frame left from its original AnyCubic Mega Zero v1 spec.

I even designed and made a bunch of aluminum parts for it on my little CNC machine.

My printer and CNC machine have both made basis parts for each other, which is kinda hilarious.

I've been following the debate for the last few days, and have learnt a lot - thanks all!

I think I've concluded, that if I wanted a largely plug and play 3D printer and had about £1k to spend, the Bambu X1C (Bambu Lab X1 Carbon 3D Printer | Bambu Lab UK) would not be a terrible shout?

Correct. Although I still say if you aren't interested in hard to print materials, the P1P or P1S is a fine option too. Especially if you are brand new to printing, and don't even know how often/extensively you will use it.

I find zero reason to print ABS or PC for my needs, especially with CF laced PETG or PLA these days. So an X1 would be a waste for me.

If your printing anything that will be marine grade or withstand those elements you’d want to print with ABS or PETG at a minimum.

No argument. That said, PETG doesn't require an enclosure, and PETG-CF may get you 'close enough' to not need ABS at all.

ABS has its place, although less so now that there are a lot of other material options/formulations - depends if you need strength, impact resistance, or chemical resistance (and which chemical) though.

Yeah no doubt. I have 400g of saltwater aquariums and print a lot of stuff for that where ABS is required in my eyes. But I also bought the Prusa enclosure with my MK4 kit and love the combo. But as you said, everything has its place.

No doubt! There are a zillion different filament materials for good reason. ![]()

This...^^^

I don't like that the Bambu printers are a closed system (prefer fully open-source HW/FW/SW options) but the Bambu sounds so easy to get up and printing, and prints very quickly. Once you get past the "oh that's cool" phase my experience is you're mainly going to want to print things quickly and with good quality, which the Bambu does.

It isn't a "religious war" thing for me. There are lots of good printers out there.

As more of a hobbyist, and not someone trying to make money off a print farm, I just want the damn thing to work - and work without a bunch of fuss, preferably the 1st time, when I want to print something. I'm completely uninterested in fiddling with a dozen setting to try and dial in a perfect print at this point.

Bambu has been very good for me in those areas. Other printers probably would be too, but the Bambu is the one I'm currently using.

I can't say the same for my FLSun SR or my Creality Ender 3 S1 Pro.

My $300 Solvol SV05 has been like this - started up and worked, and kept working. My only "complaint" was that I quickly wished it was faster.

I changed FW to Klipper on a Pi, and optimized what I could (input shaping, pressure advance calibration, adaptive mesh, etc.) and was able to increase speeds and keep quality, etc. Luckily I enjoy doing the tweaking projects, and since I don't really have a regular need for 3D prints and didn't want to spend much over $300 for a printer, my approach worked well for me overall. I can see how others would not enjoy that journey... ![]()

![]()

PETG won’t Survive our Aussie Sun, ABS is the bare minimum for outdoor prints here. ASA is better still.

Another good point - outdoor prints require special considerations, too.

Even here in Texas, USA ABS will degrade quicker than some expect and our UV levels are a bit (though not that much) lower than average Australia.

I've never tried any of the UV resistant specific PETG variants (UV-PETG / PETG UV / etc. There are multiple of them out there), so can't comment on those. I would guess none of them would be better than ASA though.

Fumes as bad as ABS?

Nozzle & bed temps?

I find the fumes from Prusa ASA are much less than pure ABS. I run my bed at 110c and nozzle at 265c.

I was wondering about the fumes too. Good to hear it at least isn't worse than standard ABS (which is awful - to me).

Agreed, standard ABS smells horrid and is quite toxic.

How would you rate its warping tendency vs ABS? Just curious.

Everything I read says it warps, but my only comparison on 'tendency to warp' is ABS so that would be a more useful comparison for me.

ASA is a little better than ABS for warping, but you still need to ensure there are no drafts or air currents if you want to print it on an open frame printer.

You also need to keep part cooling to the bare minimum, I run mine at ~15%.

My Ender 3-V2 was a constant source of frustration, always needing adjustments just to get something to print decently.

It frustrated me so much that I almost gave up on 3D printing.